|

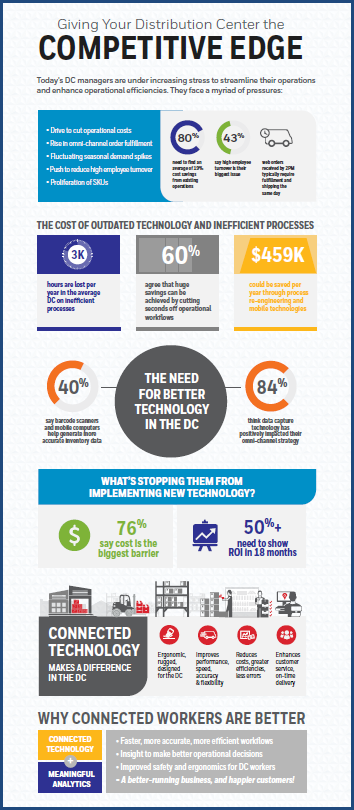

Distribution centers, having a heavy and poignant role in customer on-time delivery and satisfaction, need the best systems and software to process materials' high throughput requirements.

Sources: Honeywell/YouGov study; Peerless Sensors Survey; Modern Materials Handling presentation, “Automation Boom”; Fox Racing case study; Camp Pendleton case study; Mission Foods case study; Plant Access case study; Supply Chain Digest Magazine: A User's Perspective on Distribution Technology Alternatives; The ABCs of DCs, Global Supply Chain Institute

Summary When considering WMS software, connecting materials, technology, and people to save cost, it makes sense to implement an WMS system. Well organized workforces make cost savings easier while closing the gap on material management outages and planning cycles. Newsletter subscription options:

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

September 2022

Categories |

RSS Feed

RSS Feed