What do ERP, BOM, and ECC (engineering change control) have in common with engineering? Shared data, collaborative information, and integration features. Let's take them one at a time and see how the interplay helps companies in each stage of change management. ERP is the cornerstone of business management for manufacturers and other collaborative enterprise systems. Such as CRM, WMS, and MOM. (extended business functions; customers, warehouse, and operations automation.)

Within ERP, we have these systems and more:

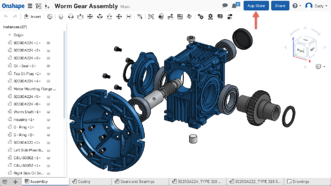

BOM - Bill of Materials The bill of materials for the Boeing 747 includes more than 6 million parts, and the BOMs for the 767 and 777 contain more than 3 million parts each. To make things even more complex, all those parts are subject to the intensive quality and reliability checks, and they are inspected multiple times before, during, and after they are installed. We are considering that all parts, regardless of end-product, require extensive management, engineering, and accountability. When materials specifications change, what does the company do to process these changes? What purchase decisions must be made. Which jobs and sales orders get the new parts and which get the old design? What time frames do the materials cycle through inventory? Are the old materials scrapped, recycled, or held as obsolete? Does engineering change happen in ERP or only on design teams’ computers? What controls can be used to manage change to ensure mistakes get reduced to a minimum? BOM can help manage inventories, product management, phasing of materials, and parent-item ongoing modifications. Some of those tools include:

ECC is an engineering change control, configuration management system within ERP. When a product needs changes after being released to production, the process can be disruptive and messy. Engineering change control can help. Dynamic engineering change control requires that as soon as the identified changes are determined, engineering can search the ERP database to identify all of the parts or products that might be affected by the change - called a "where-used" search. The ERP database provides a comprehensive list of inventory on-hand, inventory on-order (from either purchases or in-process production), planned purchasing or production activity, and customer orders in hand or forecasted for the part that is changing and all higher-level affected part and products. ECC Processes generally include:

When an item is under ECC-control, all updates and changes to those items must, by design, go through the processes defined by the system. Engineering document control is managing the manufacturing, purchase, sales, and distribution. Some changes, such as cosmetic and other non-critical changes, can be done immediately without a review process. However, all changes get documented in the ECC system, dates, times, operators, and descriptions captured. Summarizing ERP, BOM, ECC form modules of software systems designed to assist manufacturers in managing materials, change, production, sales, vendors and customers; documenting each step with assurances of quality-controlled process results. Manufacturers' products change frequently. By having tools within your operations software arsenal supporting change as required allows the freedom to run your business without fear of things falling through the cracks. What you don’t see can hurt you. Having the software skill-sets built-in allows you more degrees of freedom. Newsletter subscription options:

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorWrite something about yourself. No need to be fancy, just an overview. Archives

September 2022

Categories |

RSS Feed

RSS Feed